ELENCO PRODOTTI

HDFW-6E High efficiency vegetable washing machine leeks green onions cleaning machine

Dettagli del prodotto:

| Luogo d'origine: | Zhengzhou,Henan,Cina |

|---|---|

| Marchio: | HUAFOOD |

| Certificazione: | ISO,CE,SGS |

| Numero di modello: | HDFW-6E |

video

Parametri

This is a complete processing line, suitable for various types of vegetables, such as carrot, Patata, cavolo, cipolle, eccetera.

Scenari applicabili: supermercati, ristoranti, piante di trasformazione alimentare, piante di congelamento, dried fruit processing plants,snak processing factory

| Produzione totale della linea di lavaggio delle carote 500-1000 kg / H | ||

| Articolo | Energia | Misurare |

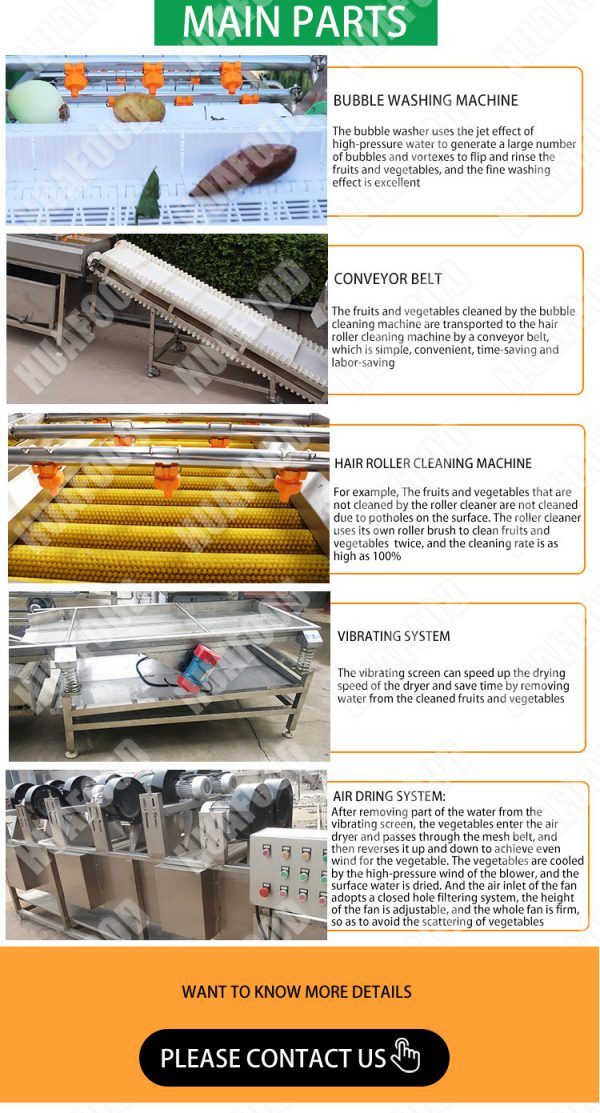

| Bubble Washing Machine | 3.75kW/380 V/50 Hz | 4000*1200*1300mm |

| macchina di sollevamento | 0.75kW/380 V/50 Hz | 2000*1000*1900mm |

| Macchina per la pulizia del rullo per capelli | 2.0kW/380 V/50 Hz | 2000*1000*1300mm |

| macchina vibrante | 1.5kW/380 V/50 Hz | 1500*1000*1300mm |

| macchina per l'asciugatura dell'aria | 15kW/380 V/50 Hz | 4000*1200*1400mm |

| Nota: Questi parametri sono convenzionali e possono essere personalizzati in base alle esigenze del cliente | ||

.

Principio di funzionamento

procedura

1.Il primo passo è mettere le verdure e i frutti che devono essere puliti nella lavatrice per la pulizia;

2.Il secondo passo consiste nell'utilizzare la cintura del trasportatore per trasferire frutta e verdura lavati nella lavatrice per la rulmine per la pulizia secondaria per garantire che le verdure siano pulite 100%;

3.Il terzo passo è rimuovere parte dell'acqua dalla frutta e dalle verdure attraverso lo schermo vibrante;

- Il quarto passo è rimuovere tutta l'acqua dalla frutta e dalle verdure dallo schermo vibrante nell'essiccatore d'aria;

5.Il quinto passo è tagliare la frutta e le verdure pulite in base alle esigenze

Finalmente, in base alle tue esigenze, puoi tagliare, Asciutto, congelare, pacchetto, eccetera.

Vegetable processing machinery

Talenti

1. The equipment is cleaned in two stages before and after the two stages. The internal circulating water is cleaned at all levels, and the spray rack is connected to the tap water for secondary cleaning.

2. The spray water pressure is adjustable, and the bubbling volume is adjustable.

3. Sterilizzazione UV, ozone sterilization

4. Both sides of the baffle 70mm, conveyor belt material POM, velocità regolabile, with the inverter. The cleaning time depends on the actual speed.