LISTA DE PRODUTOS

HDF-TH10 rice grain packing machine Automatic weighing machine

Detalhes do produto:

| Lugar de origem: | Zhengzhou,Henan,China |

|---|---|

| Marca: | HUAFOOD |

| Certificação: | ISO,CE,GV |

| Número do modelo: | HDF-TH10 |

Pagamento & Termos de envio:

| Quantidade mínima de pedido: | 1 conjuntos |

|---|---|

| Velocidade de embalagem | 25-65 sacos/min |

| Packaging range | 10-200g |

| Granularity | 0.05-25milímetros |

| Single grain weight | 0.02-1g |

| Termos de pagamento: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

Vídeo

Parâmetros

| Estilo de bolsa | Weighing packaging machine |

| Velocidade de embalagem | 25-65Bolsa/min |

| Packaging range | 10-200g/bag |

| Single grain weight | 0.02-1g |

| Precision | ±0.5 |

| Consumo de energia | 220v/50Hz/2.8kw |

| Material | Aço inoxidável |

| Peso | 200kg |

| Dimensões | 750*1280*1950milímetros |

| Observação | Cooperating with sealing machine,Can match pneumatic(air or nitrogen) |

Princípio de trabalho

The grain packaging machine consists of a vibration mechanism, a door opening mechanism and a weighing control system. It uses electromagnetic vibration and high-precision weighing control technology to achieve extremely high repeatability. It uses two-stage vibration and door opening, not only The material time is short, and the measurement accuracy is high, and the shape of the material is not damaged.

The host computer adopts microcomputer and light control switch control, and has functions of automatic metering filling, weighing feedback, automatic correction error, out-of-tolerance alarm, counting, keyboard setting and correction. The hopper is made of anti-corrosion stainless steel and does not contain contaminants. With high sensitivity, high precision and high reliability, it can meet the packaging needs of different specifications.

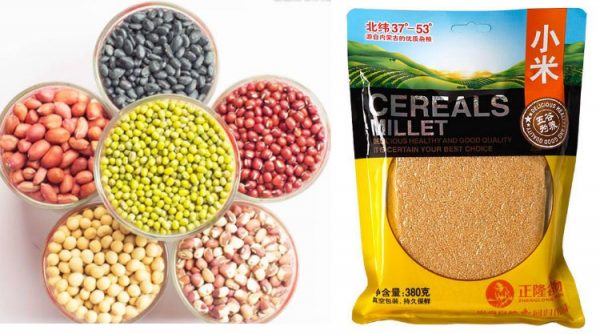

The weighing packing machine is suitable for quantitative filling of uniform granular materials, such as salt, seeds, food, chemical, washing and other industries.

Recurso

1. The electronic scale is directly measured, and the loading is more accurate;

2. Double vibration feeding, higher efficiency;

3. Artificial suit, spot sensing;

4. Weighing: Electronic scale measurement;

5. Fast speed: double vibrating feed or multi-vibration feed;

6. Low noise: no mechanical transmission;

7. Strong corrosion resistance: stainless steel material;

8. Induction bag: The photoelectric port sensor is installed at the bag mouth, and the battery is not connected;

9. Less power consumption: The power of the whole machine does not exceed 250~650W.