Descrição do Projeto

LISTA DE PRODUTOS

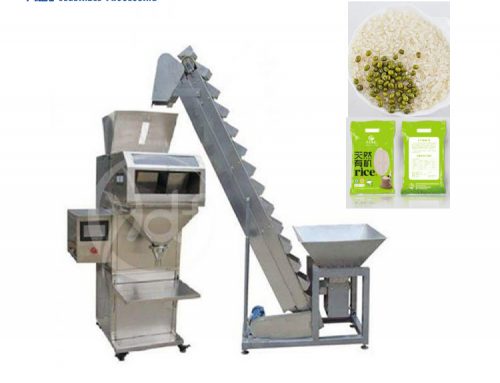

HDF-320B Auto paste packaging machine honey ketchup packing machine

Detalhes do produto:

| Lugar de origem: | Zhengzhou,Henan,China |

|---|---|

| Marca: | HUAFOOD |

| Certificação: | ISO,CE,GV |

| Número do modelo: | HDF-320B |

Pagamento & Termos de envio:

| Quantidade mínima de pedido: | 1 conjuntos |

|---|---|

| Velocidade de embalagem | 24-60 sacos/min |

| Comprimento da bolsa | 30-150milímetros |

| Largura da bolsa | 20-100milímetros |

| Filling Range | 40ml or 20-100ml |

| Termos de pagamento: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

Vídeo

Parâmetros

| Nome do Produto | Paste packing machine |

| Velocidade de embalagem | 24-60 Bolsa/min |

| Comprimento da bolsa | 30-150milímetros |

| Film width | 25-145milímetros |

| Intervalo de enchimento | 40ml or 20-100ml |

| Consumo de energia | 220v/50Hz/2.2kw |

| Air pressure | 0.6-0.7MP |

| Peso | 280kg |

| Dimensões | 1150*700*1750milímetros |

| Tamanho da caixa | 1100*750*1820milímetros |

Princípio de trabalho

The paste packaging machine integrates electromechanical integration, double cpu microcomputer control system, large-screen liquid crystal display, adopts microcomputer controlled photoelectric tracking and correction system, and is equipped with high-precision stepping motor to accurately position the same position of each package pattern, and the control system is completed. The synchronization, fixed length, positioning and speed of the whole machine automatically diagnose faults. Optional ribbon printer or stamping device. The series of actions such as bag, enchimento, counting, sealing and slitting are automatically completed.

This ketchup machine is suitable for automatic quantitative packaging of pastes and sauces in food, daily chemical and pharmaceutical industries such as tomato sauce, shampoo, face cream and seasoning.

Talentos

1. The stepper motor control (pode escolher o servo motor), o comprimento da bolsa é definido, Não precisa se ajustar vazio, one pace reachsthe designated position, Membrana da província que economiza tempo.

2. Interface homem-máquina, Configuração de parâmetros conveniente e rápida.

3. Função de auto-diagnóstico de falha, Fault Shows em uma olhada.

4. Rastreamento fotoelétrico, Posição de vedação e corte de entradas digitais, mais preciso na posição de vedação e corte.

5. Controle de PID independente de temperatura, mais adequado a uma variedade de materiais de embalagem.

6. Posicionando a função de parada, facas antiaderentes, Não desperdice envelope.

7. O sistema de transmissão é conciso, mais confiável, Manutenção mais conveniente.

8. Todo controle pela implementação do software, Ajuste conveniente da função e atualização da tecnologia, Mantenha -se avançado.